The Role of Petrochemicals in Electric Vehicle (EV) Manufacturing

Introduction

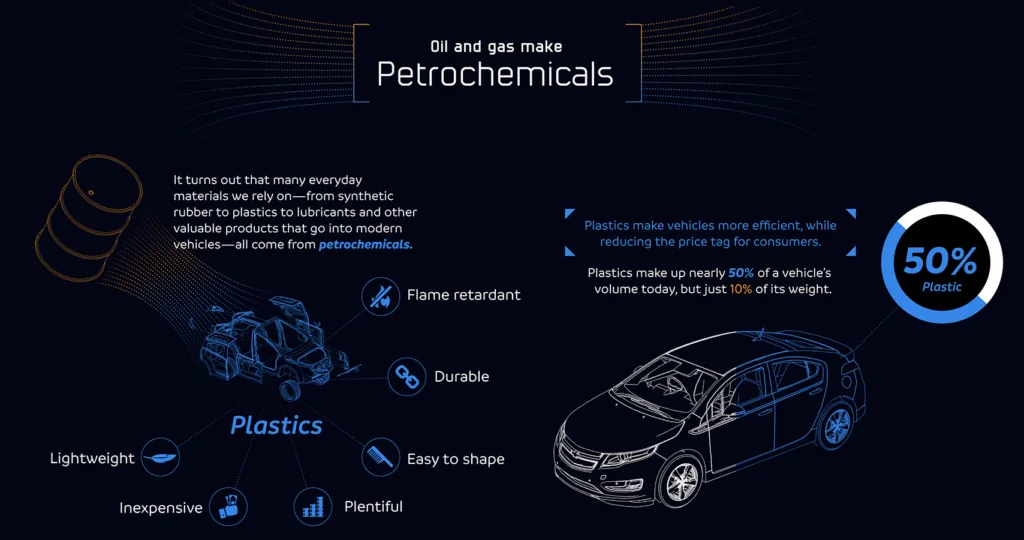

The global shift toward electric vehicles (EVs) is not just a transformation in the automotive sector but also in the petrochemical industry. While EVs are often associated with “clean energy” and reduced fossil fuel consumption, their very foundation depends on petrochemical products. From lightweight plastics and resins to synthetic rubbers and coolants, petrochemicals remain at the heart of EV design and production.

For exporters, this growing demand opens a new horizon: supplying raw petrochemical materials that are critical to the EV value chain.

Why Petrochemicals Are Essential for EV Manufacturing

Lightweight Materials for Energy Efficiency

EVs rely on polypropylene, polyethylene, and polycarbonate to reduce weight and extend battery range.

Battery Components

Petrochemical derivatives like ethylene carbonate and vinylene carbonate are used in lithium-ion battery electrolytes.

Interior & Exterior Design

ABS resins, polyurethane foams, and acrylics provide durability, safety, and aesthetics.

Tires & Safety Systems

Synthetic rubbers and high-performance polymers are used in EV tires and safety components.

Thermal Management

Monoethylene glycol (MEG) and other coolants help regulate battery and motor temperatures.

Table 1: Petrochemical Products in Key EV Components

| EV Component | Petrochemical Material Used | Function/Benefit |

|---|---|---|

| Battery Electrolyte | Ethylene carbonate, solvents | Conductivity, energy storage |

| Body Panels | Polypropylene, polycarbonate | Lightweight, impact resistance |

| Interiors | ABS, polyurethane, acrylics | Comfort, safety, design flexibility |

| Tires | Synthetic rubber, elastomers | Durability, grip, lower rolling resistance |

| Cooling Systems | Monoethylene glycol, coolants | Thermal stability & battery protection |

How EV Growth Shapes Petrochemical Demand

Rising Battery Production → Increased demand for carbonate solvents and specialty chemicals.

Lightweight Vehicle Design → Higher use of polymers instead of steel and aluminum.

Sustainability Pressure → Push for recyclable polymers and bio-based alternatives.

Regional Export Opportunities → Countries like India and China, with booming EV markets, are driving demand for petrochemical imports.

Table 2: Projected Petrochemical Demand from EV Sector (2023–2030)

| Year | Global EV Sales (Million Units) | Petrochemical Demand (Million Tons) | Key Drivers |

|---|---|---|---|

| 2023 | 10 | 5.2 | Battery & interiors |

| 2025 | 16 | 8.1 | Lightweight materials |

| 2030 | 30 | 15.5 | Mass EV adoption |

Opportunities for Exporters

Specialty Solvents & Additives – Growing demand for battery-grade chemicals.

High-Performance Polymers – EV makers require lighter, safer materials.

Emerging Markets – India, Southeast Asia, and Africa will depend heavily on imports.

Recycling Partnerships – Supplying circular petrochemical products to EV producers.

Challenges to Consider

Environmental Regulations → Pressure to adopt greener feedstocks.

Volatile Oil Prices → Affect costs of petrochemical derivatives.

Competition → Global suppliers (China, USA, Middle East) all target EV markets.

Innovation Race → Constant need for advanced materials to meet new EV standards.

Future Outlook

By 2030, EVs could represent more than 30% of global car sales, translating into a massive petrochemical demand surge. Exporters who adapt by supplying battery chemicals, high-strength polymers, and recyclable plastics will secure long-term contracts with global EV manufacturers.

Would you be looking for suppliers in Iran ?

- Contact Us today and get connected with producers and export-ready logistics.

- sales@PetroExportHub.com

Related posts

Mono Ethylene Glycol (MEG) serves as a cornerstone for modern antifreeze and coolant formulations, offering reliable freezing protection and heat resi . . .

Explore Solvent 100’s specs, uses, and export opportunities from Iran. Ideal for paint, ink, and adhesive buyers in India, Turkey, UAE, and Africa. . . .

Explore everything you need to know about exporting sulphur from Iran in 2024 — including types, packaging, documents, ports, prices, and top import . . .

Explore Iran’s top ports for petrochemical exports, including Bandar Imam Khomeini, Assaluyeh, and Bandar Abbas. Compare infrastructure, accessibili . . .

Learn the key differences between polypropylene (PP) and polyethylene (PE), their applications, advantages, and how to choose the right polymer for yo . . .

Discover how a Turkish plastics manufacturer reduced costs by 22% through importing HDPE from Iran. Real-world case study by PetroExportHub. . . .

Learn why Iran is a leading exporter of polyethylene (PE). Discover grades, global applications, and how PetroExportHub connects buyers with top suppl . . .

We are here to answer your questions....

Petro Export Hub

PetroExportHub specializes in the export of premium-grade petrochemicals, minerals, and industrial chemicals from Iran, serving international markets with reliability, transparency, and tailored logistics solutions

Tehran Office

Phone:

+989127607241

Address:

Tehran..

German Office

TEL :

+4915161647487

Address:

Heilsbronne 99441, Nuremberg

Quick Access

Quick Access

- Contact Our Sales Team

- Frequently Questions

- Shipping & Logistics

- Become a Partner

- Certificatins & Quality