Global Demand Shift: Is PE80 Making a Comeback?

Introduction

For years, the global HDPE pipe industry has been dominated by PE100. With its higher strength and durability, many thought PE80 would fade into history. But in recent months, a subtle shift has been noticed in procurement patterns and project tenders. The question arises: Is PE80 making a comeback? And if so, why are buyers re-evaluating a grade that was once considered “second choice” compared to hdpe pe100 pipe?

1. Why PE100 Took Over in the First Place

Stronger & Thinner Walls: PE100 could achieve higher pressure ratings with thinner pipe walls.

Long-Term Reliability: Its resistance to stress cracking and long lifespan made it ideal for infrastructure.

Global Standards: Many hdpe pe 100 pipe specifications began prioritizing PE100, pushing PE80 to the background.

The result? For more than a decade, most large-scale water and gas projects relied heavily on pe100 pe80 comparisons but leaned toward PE100.

2. What’s Driving Renewed Interest in PE80?

Cost Sensitivity – In markets facing rising raw material costs, PE80 is more affordable and still meets many project requirements.

Medium-Pressure Projects – Not all systems demand the strength of PE100. Irrigation, rural water supply, and small gas networks often work perfectly with PE80.

Supply Chain Disruptions – With occasional shortages in hdpe pe100 pipe, buyers are looking for reliable alternatives.

Sustainability Factors – Thinner PE80 products may reduce material use and transport costs in certain applications.

3. Market Outlook in 2025

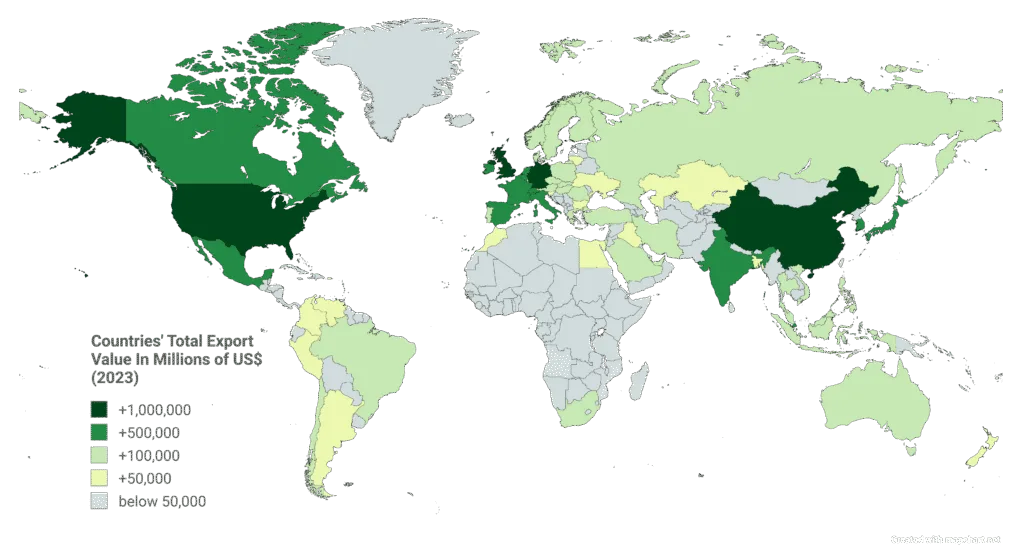

In regions such as South Asia, Africa, and parts of the Middle East, governments are expanding water infrastructure but facing budget limitations. Here, PE80 is regaining traction. Exporters offering both pe100 pe80 options are finding new opportunities to serve these price-conscious markets.

Interestingly, even in developed markets like Europe, tenders for low-pressure irrigation and rehabilitation projects are beginning to specify PE80 again.

4. Should Exporters Invest More in PE80?

While PE100 will remain the standard for high-pressure gas pipelines and large-scale transmission mains, exporters shouldn’t ignore the renewed demand for PE80. Having both in the product portfolio is a strategic advantage—especially when hdpe pe 100 pipe specifications allow PE80 for certain applications.

Conclusion

PE80 may never fully replace hdpe pe100 pipe, but its role in global markets is far from over. In fact, economic pressures and diversified project needs are pushing it back into the spotlight. For suppliers and exporters, the smart move is to stay flexible—offering PE100 where performance is non-negotiable, and PE80 where affordability and practicality take priority.

Global infrastructure trends show that PE80, once overshadowed by PE100, is regaining interest. Cost-sensitive markets see PE80 as a practical alternative for medium-pressure projects. Supply disruptions in hdpe pe100 pipe have also encouraged buyers to reconsider PE80. Exporters providing both pe100 pe80 options can serve a broader range of markets. The 2025 outlook suggests PE80 has a valuable niche in the evolving HDPE industry.

Cost Advantage – PE80 offers budget-friendly solutions for medium-pressure systems.

Reliable Performance – Still meets many hdpe pe 100 pipe specifications for water and gas.

Market Flexibility – Exporters offering pe100 pe80 cover wider buyer needs

Rising Demand – Shortages of hdpe pe100 pipe are fueling interest in PE80 again.

Looking for HDPE PE80 suppliers in Iran ?

- Contact Us today and get connected with producers and export-ready logistics.

- sales@PetroExportHub.com

Related posts

Mono Ethylene Glycol (MEG) serves as a cornerstone for modern antifreeze and coolant formulations, offering reliable freezing protection and heat resi . . .

2 minute

Read more

Explore Solvent 100’s specs, uses, and export opportunities from Iran. Ideal for paint, ink, and adhesive buyers in India, Turkey, UAE, and Africa. . . .

3 minute

Read more

Explore everything you need to know about exporting sulphur from Iran in 2024 — including types, packaging, documents, ports, prices, and top import . . .

2 minute

Read more

Explore Iran’s top ports for petrochemical exports, including Bandar Imam Khomeini, Assaluyeh, and Bandar Abbas. Compare infrastructure, accessibili . . .

2 minute

Read more

Learn the key differences between polypropylene (PP) and polyethylene (PE), their applications, advantages, and how to choose the right polymer for yo . . .

2 minute

Read more

Discover how a Turkish plastics manufacturer reduced costs by 22% through importing HDPE from Iran. Real-world case study by PetroExportHub. . . .

2 minute

Read more

Learn why Iran is a leading exporter of polyethylene (PE). Discover grades, global applications, and how PetroExportHub connects buyers with top suppl . . .

1 minute

Read more

We are here to answer your questions....

+ 989127607241

Petro Export Hub

PetroExportHub specializes in the export of premium-grade petrochemicals, minerals, and industrial chemicals from Iran, serving international markets with reliability, transparency, and tailored logistics solutions

Tehran Office

Phone:

+989127607241

Address:

Tehran..

German Office

TEL :

+4915161647487

Address:

Heilsbronne 99441, Nuremberg

Quick Access

Quick Access

- Contact Our Sales Team

- Frequently Questions

- Shipping & Logistics

- Become a Partner

- Certificatins & Quality