How to Choose Between Aromatic Solvents: Comparing Solvesso 100, Xylene, and Toluene

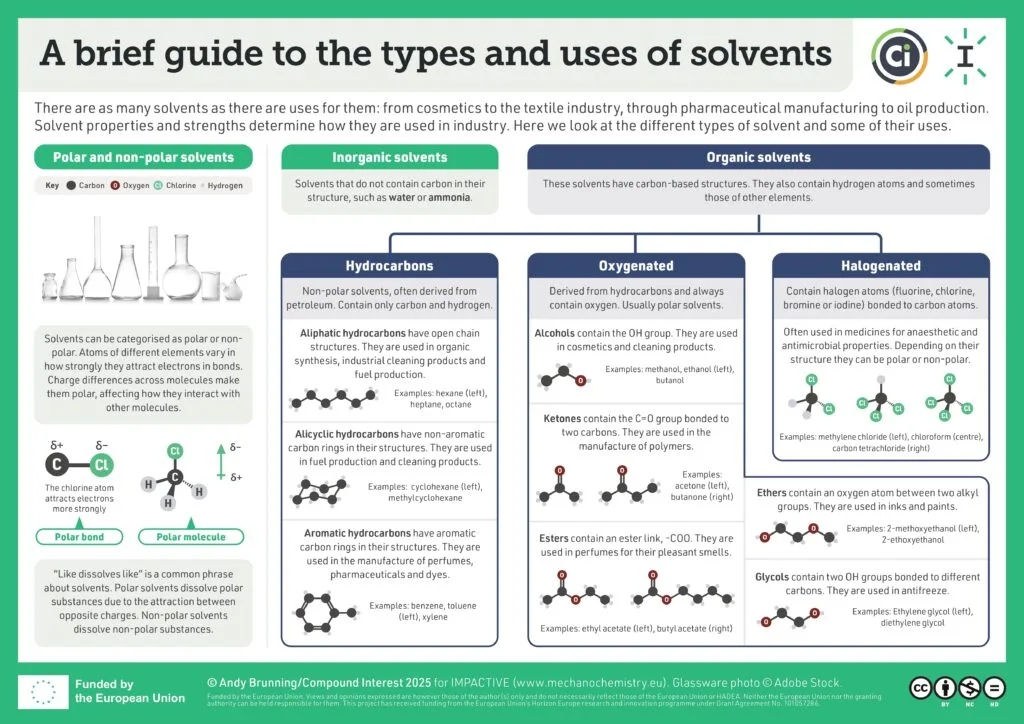

When it comes to aromatic solvents, buyers in coatings, adhesives, and chemical industries often face a key question: Should I choose Solvesso 100, Xylene, or Toluene? Each solvent has unique physical properties, cost implications, and safety considerations. Understanding these differences is critical for formulators and procurement teams looking to optimize performance while managing costs.

Why the Choice Matters

Solvesso 100 (also known as Aromatic 100) is favored for controlled evaporation and lower odor levels in industrial coatings and inks.

Xylene solvent is widely available and cost-effective but comes with higher volatility.

Toluene solvent offers strong solvency power, but safety and regulatory concerns are significant factors.

The Solvesso 100 price is usually higher than toluene but more stable due to its less volatile nature, while xylene solvent is often influenced by refinery cycles and regional supply.

Key Factors to Compare

1. Performance in Applications

Solvesso 100: Excellent balance of solvency and slower evaporation, ideal for resins, varnishes, and high-end coatings.

Xylene: Common in paints and adhesives where fast drying is required.

Toluene: Strong solvency for inks, adhesives, and agrochemicals but declining in use due to environmental restrictions.

2. Health and Safety

Solvesso 100: Lower acute toxicity, less odor, easier to handle.

Xylene: Moderate toxicity; requires ventilation.

Toluene: Classified with stricter handling rules; substitution is trending upward in Europe and North America.

3. Price and Supply Dynamics

Solvesso 100 price: Influenced by crude oil and naphtha but more stable in long-term contracts.

Xylene solvent: Priced lower, widely available from refineries, but highly cyclical.

Toluene solvent: Generally cheapest, but higher regulatory compliance costs may offset savings.

Comparative Table: Solvesso 100 vs. Xylene vs. Toluene

| Criteria | Solvesso 100 (Aromatic 100) | Xylene Solvent | Toluene Solvent |

|---|---|---|---|

| Boiling Range | 160–180 °C | 138–144 °C | 110–111 °C |

| Evaporation Rate | Slow / controlled | Medium | Fast |

| Odor & Handling | Lower odor, safer handling | Moderate odor, requires ventilation | Strong odor, stricter handling |

| Typical Uses | Resins, coatings, inks, adhesives | Paints, adhesives, cleaning agents | Inks, adhesives, agrochemicals |

| Market Price Trend | Mid-to-high; Solvesso 100 price stable | Lower; cyclical volatility | Lowest; but compliance adds cost |

| Environmental Outlook | More acceptable under VOC rules | Moderate restrictions | Heavily restricted in EU/US |

Practical Buying Guide

Choose Solvesso 100 if stability, performance in coatings, and compliance with VOC regulations are priorities.

Choose Xylene solvent if you need a balance of cost and drying time in mass-market paints.

Choose Toluene solvent only if maximum solvency is required and regulations allow its use.

Solvesso 100: Balanced solvent with stable pricing and better regulatory acceptance.

Xylene solvent: Cost-effective, widely used in paints and adhesives.

Toluene solvent: Strong solvency but facing strict environmental limits.

Decision factor: Price vs. safety vs. compliance drives solvent selection.

Looking for solvesso suppliers in Iran ?

- Contact Us today and get connected with producers and export-ready logistics.

- sales@PetroExportHub.com

Related posts

Mono Ethylene Glycol (MEG) serves as a cornerstone for modern antifreeze and coolant formulations, offering reliable freezing protection and heat resi . . .

Explore Solvent 100’s specs, uses, and export opportunities from Iran. Ideal for paint, ink, and adhesive buyers in India, Turkey, UAE, and Africa. . . .

Explore everything you need to know about exporting sulphur from Iran in 2024 — including types, packaging, documents, ports, prices, and top import . . .

Explore Iran’s top ports for petrochemical exports, including Bandar Imam Khomeini, Assaluyeh, and Bandar Abbas. Compare infrastructure, accessibili . . .

Learn the key differences between polypropylene (PP) and polyethylene (PE), their applications, advantages, and how to choose the right polymer for yo . . .

Discover how a Turkish plastics manufacturer reduced costs by 22% through importing HDPE from Iran. Real-world case study by PetroExportHub. . . .

Learn why Iran is a leading exporter of polyethylene (PE). Discover grades, global applications, and how PetroExportHub connects buyers with top suppl . . .

We are here to answer your questions....

Petro Export Hub

PetroExportHub specializes in the export of premium-grade petrochemicals, minerals, and industrial chemicals from Iran, serving international markets with reliability, transparency, and tailored logistics solutions

Tehran Office

Phone:

+989127607241

Address:

Tehran..

German Office

TEL :

+4915161647487

Address:

Heilsbronne 99441, Nuremberg

Quick Access

Quick Access

- Contact Our Sales Team

- Frequently Questions

- Shipping & Logistics

- Become a Partner

- Certificatins & Quality